BYD’s exhibition hall occupies two floors, and the staff gave us a detailed introduction (in fluent English) to BYD’s 30-year development history and major technological breakthroughs, including blade batteries, the DM-i super hybrid system, their e-platform, Yi Sifang and Yun Nian, and so much more.

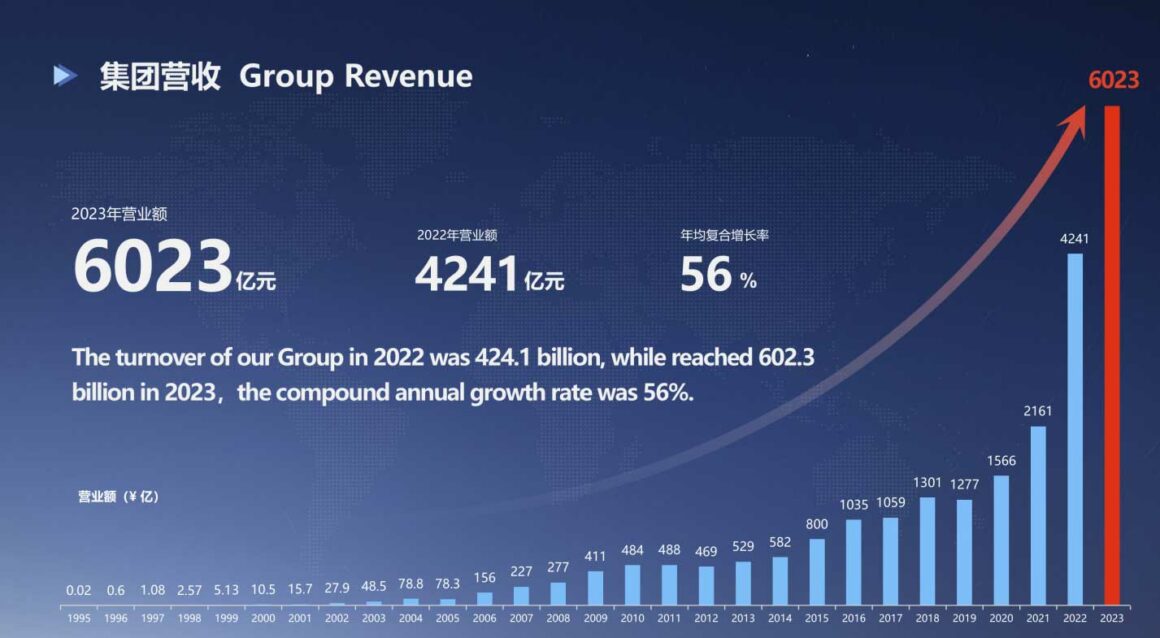

On 18 November 1994, Wang Chuanfu gathered a team of 20 people and founded BYD in Buji Town, Longgang District, Shenzhen. The formal founding date was 10 February 1995 as Shenzhen BYD Battery Company Limited, with a focus on rechargeable nickel–cadmium (NiCd) batteries.

BYD comprise four business units: Electronics, Auto, Renewable Energy, and Rail Transit. The rail transit is purely electric, including the BYD Cloud Rail; the BYD headquarters has also a cloud rail service, so that employees can take the shuttle between the buildings.

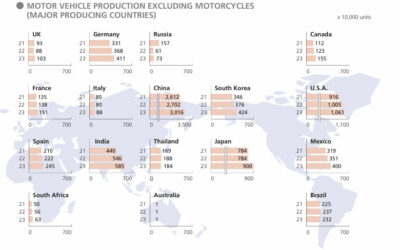

In 2024, BYD was the № 2 electric vehicle battery producer (after CATL), producing 17.2 per cent of the world’s EV batteries. As of September 2024, BYD employs 900,608 people, of whom 104,003 work in R&D.

BYD Group’s revenue has evolved like a skyrocket: from 0 in 1995 to $83bn in 2023:

BYD’s largest subsidiary, BYD Auto, was founded in 2003. In 2022 they stopped ICE vehicle production to focus on PHEV and BEV cars.

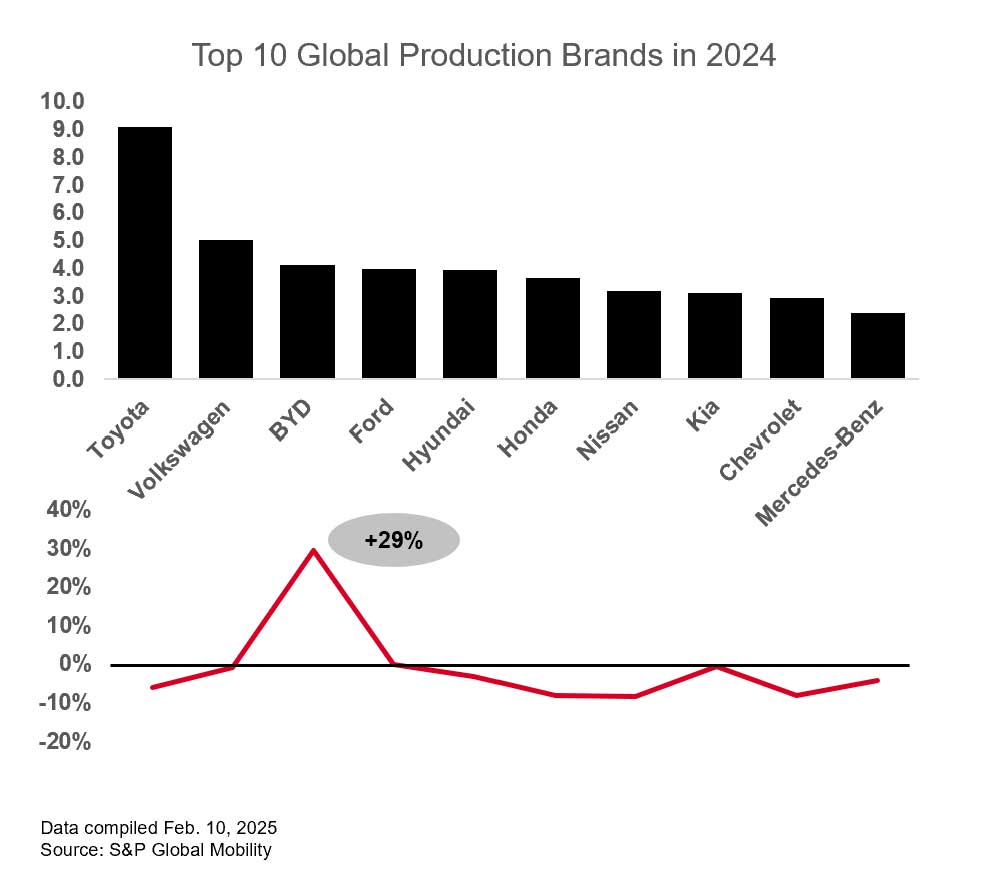

BYD Auto are ranked the № 3 automaker in 2024 by S&P with 29-per-cent growth, while all the other top-10 OEM brands were stable or had decreasing revenues:

BYD make five car marques: BYD Dynasty, BYD Ocean, Fangchengbao, Denza, and Yangwang.

There are BYD Auto plants in China, Brazil, Thailand, and one is in the works for Hungary (for Europe in 2025). BYD’s vertical integration is unique and quite striking, for the company as a whole and for vehicle lighting. Their 13th Division Lamp Factory is responsible for development and production of lamps, and BYD Semiconductor is responsible for the production of semiconductors, including LEDs.

In 2003 they started lamp design in Shanghai. The first lamp plant came onstream in 2005. There are now two R&D centres (at Shenzhen and Xi’an) and nine factories. The business scope of the 13th Division Lamp Factory includes interior and exterior lighting, HUDs, and rearview mirrors. From C¥5.81m revenue in 2012, revenue in 2024 reached C¥14bn (~€1.8bn), with 40-per-cent growth in 2024. The R&D team has 600 engineers with a plan this year to reach 700.

The 13th Division Lamp Factory also supplies outside customers like Changan, Toyota, Dongfeng, and Great wall. But BYD Auto are their main customer, generating 80 per cent of divisional revenue. BYD Auto also work with other suppliers like Koito, Xingyu, Hella, and Valeo for 10 to 20 per cent of their total lighting purchases.

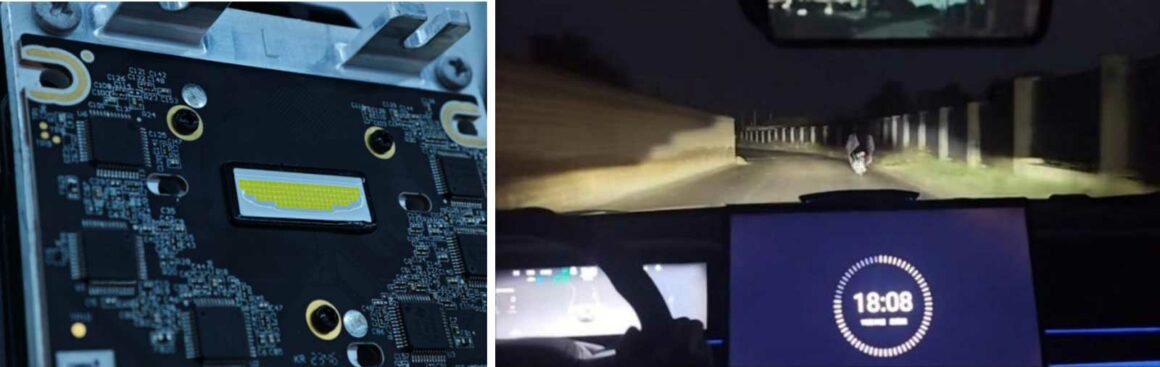

The 13th Division Lamp Factory started their first SMT line in 2018, and now have 100 SMT lines. The first xenon lamp was made there in 2013, followed by the first LED headlamp (2017), first CAN headlamp and LIN rear lamp (2020), and first DLP headlamp (2025).

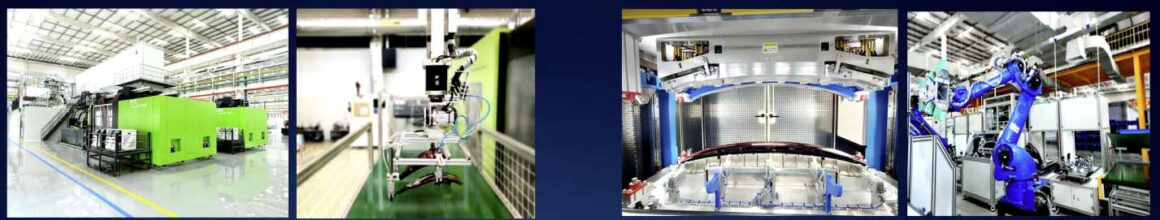

They have all skills in-house for design and testing of hardware and software. For process, the main focus at BYD Group (and therefore at the 13th Division Lamp Factory) is automation, including injection, coating, metallization, and assembly line work; it’s a zero-worker shop, as shown here:

Recent developments include high tech lighting for vehicles from the maker’s Denza and Yangwang brands.

As example, the BYD Denza Z9 and some Yangwang models have a five-row, 108-pixel ADB module developed and built all in-house—LEDs, module, and software.

The Yangwang U7 has DLP technology from an external supplier, and this model was launched on 27 March.

More models will be equipped with DLP optical modules from external suppliers, as well as with self-developed products. Compared to external suppliers, the self-developed products will be improved in terms of lighting effects and cost.

After a nice dinner at the BYD restaurant, the lighting team arranged a night drive of a new model: the just-released Yangwang U7. This car integrates the brand’s signature design, with the ‘door of time and space’ family design language. It has inverted-C-type matrix headlights, with recognition of the brand.

The headlight uses DLP technology and 108-pixel ADB. It supports intelligent interactive projection to achieve complex welcome scenes, personalized projections, and wall-projected movies. The full-width taillights and the high mounted stop lamp (CHMSL) are designed in continuity of the front position lamp with the lit logo between, and enhance the brand recognition:

BYD’s lighting strategy is to dramatically expand their pre-development team and to develop and promote more innovation. We concluded our exchange with a discussion about mini- and microLED technology for display applications. BYD’s lighting team also are responsible for HUDs and camera monitoring systems which are replacing side mirrors. MiniLED backlighting improves the contrast of the screen quite noticeably, and has a significant effect on PHUD (panoramic head-up displays), but the screen directly displayed by miniLED is limited to the size of LED pixel itself; it cannot provide very clear content or a good driving experience in the car yet. But it is a very good effect when used in the external lamps, even though cost and reliability challenges remain. When microLED technology matures, the relevant display technology will probably find application on high-end models, and it will provide very good customer experience.